The Ag Gas Difference

Turnkey solution

AG Gas coordinates all the pieces of the CO2 enrichment system puzzle to deliver a complete turnkey solution tailored to your site. This includes:

- CO2 Tank & Gas Supply

- Through our strategic partnership with Chart Industries and their network of gas distributors all over the country, we are able to quickly find you the best tank and gas supply options for your grow.

- If you have combined heat and power (CHP), or “Cogen”, technology on your site, we can work with your supplier to re-purpose the CO2.

- Application System

- The AG Gas CO2 enrichment system features emitter line delivery technology to flow CO2 directly into the foliar canopy, as well as data-capturing sensors to drive our algorithmic dosing.

- Life Safety

- Fully compliant with the most stringent life safety regulations, our system is equipped with safety-enhanced features extending well beyond compliance requirements to give you and your staff peace of mind.

- Permitting

- Our compliance team handles the entire permitting process for your tank and CO2 system from start to finish.

- Remote Climate Monitoring

- We provide you with a cloud-based dashboard that allows you to monitor CO2 levels, solar/light levels, temperature, humidity, and more within your grow’s foliar canopies … no matter where you are.

ag gas Co2 enrichment system

The patented AG Gas CO2 enrichment system features two key technologies that set us apart from our competitors:

- unique emitter line delivery system

- algorithmic prescriptive dosing

Our innovative technology positions us as pioneers and leaders on the market for CO2 enrichment for cannabis cultivation.

Emitter Line Delivery technology

Our arduous path emitter line delivery technology is predicated on the idea of using carbon dioxide as efficiently as possible with minimal waste. Traditional CO2 enrichment methods require flooding your entire grow space with high-pressure carbon dioxide or burning propane or natural gas to produce CO2. We provide you with a cleaner, safer, and less wasteful option.

We are the only CO2 enrichment company on the market with the technology to deliver carbon dioxide directly to your plant’s canopy. Our emitter lines evenly dispense low-pressure CO2 directly to your plants along the entire length of your beds. This efficient method lowers the amount of carbon dioxide that enters your cannabis grow space, which in turn reduces your CO2 bill. Our pioneering technology also makes it possible to use CO2 enrichment outdoors, giving open-air growers new opportunities to improve the quality of their cannabis and to dramatically increase crop yields.

Algorithmic c02 dosing

In addition to foliar canopy CO2 injection, the AG Gas system uses real-time sensor data to drive an algorithm that dynamically adjusts the dosing of your plants.

While other companies flood your grow space with large amounts of CO2 and wait until the gas reaches a certain ppm level before switching it off, the AG Gas CO2 enrichment system constantly adjusts the flow of CO2 based on photosynthetic conditions within the foliar canopy.

Our revolutionary algorithmic dosing technology allows your plants to “speak” directly with the AG Gas CO2 enrichment system. Environmental sensors and the main CO2 delivery control system communicate with each other 24/7, allowing our system to sense when the plants are ready for more carbon dioxide. If the plants are not actively photosynthesizing, our system shuts off the flow of CO2.

This algorithmic dosing technology is very effective for outdoor grow spaces, too. Our sensors monitor CO2 levels and other environmental factors such as sunlight and wind. The sensors communicate that information back to the main control system, which processes the data and determines whether the conditions are right for efficient carbon dioxide application. If it’s too windy, for example, the AG Gas CO2 enrichment system will shut off the flow of CO2; otherwise, you would lose valuable carbon dioxide to the wind.

Employing the AG Gas state-of-the-art, customizable CO2 enrichment system gives you a competitive edge in the cannabis cultivation market.

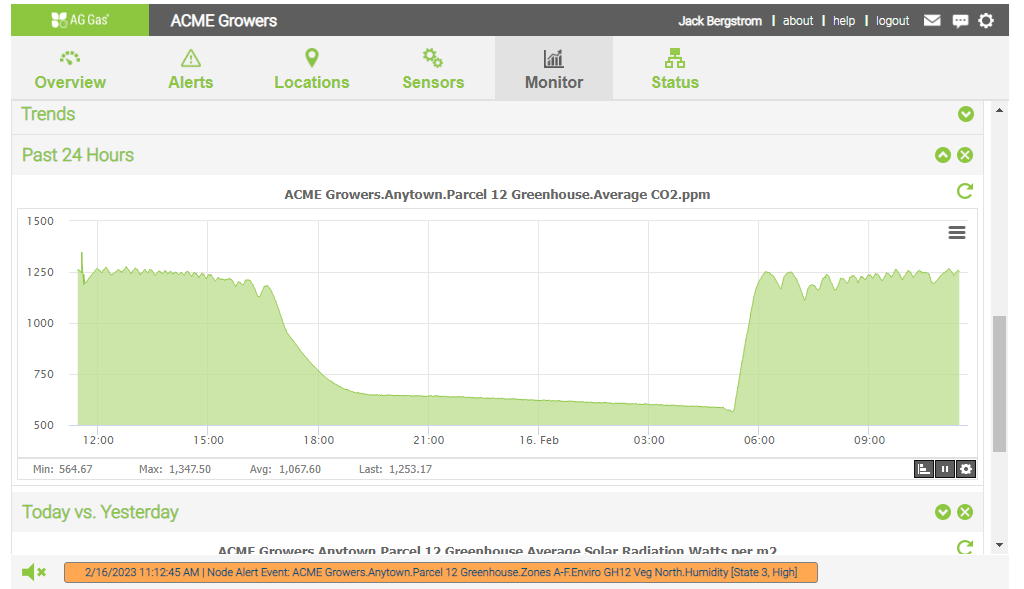

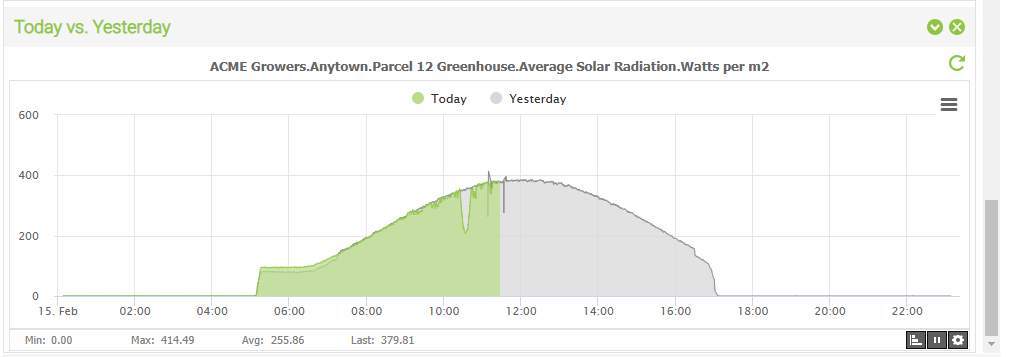

Remote climate monitoring

We offer optional dashboard access to growers to allow them to monitor not only CO2 levels within the foliar canopy, but light levels, temperature, humidity, and more, to give a real-time snapshot of your plant’s growing environment. You can also graph historical data and compare day-to-day, week-to-week, or how your parameters change throughout the year and beyond, as our system is monitoring your environment 24/7.